S=u2S(u);

Appendix 1: AT-Cut alpha-Quartz Resonator

(See: Microsystem Design by Stephen D. Senturia, pp. 192-193, 570-577)

(See: An Introduction to the Theory of Piezoelectricity by Jiashi Yang, pp. 89-93)

1 Linear Piezoelectricity

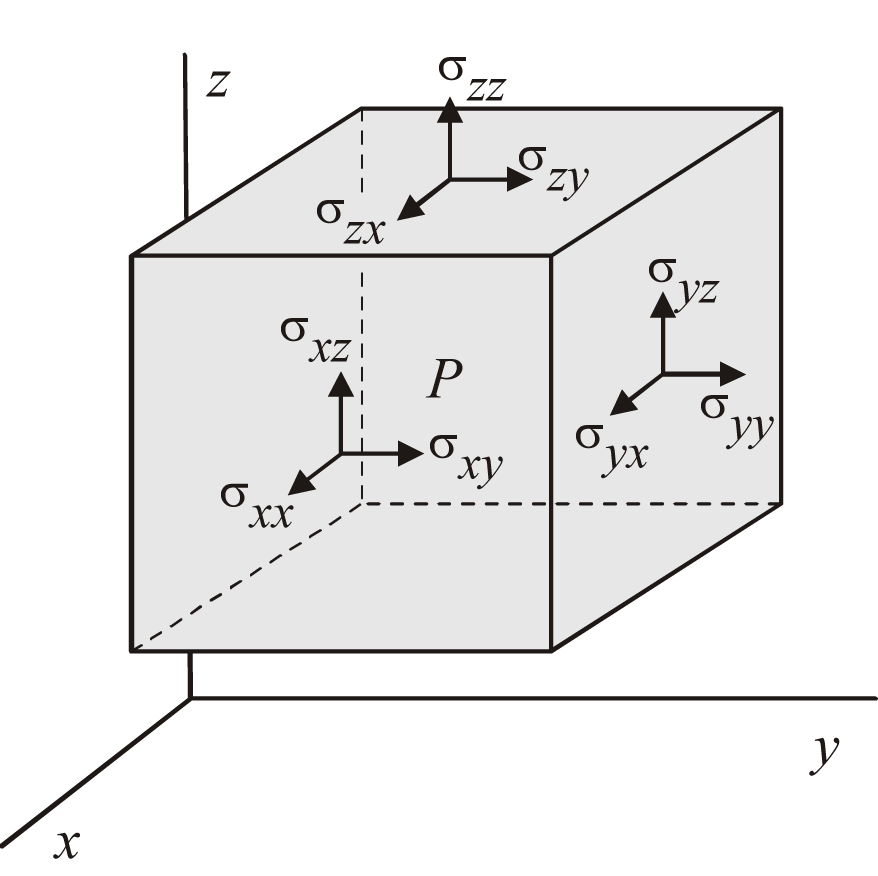

1.1 Displacement (u), Strain (S), and Stress (T)

u: displacement [m]

(%i1)

u:matrix([u_x(x,y,z,t)],[u_y(x,y,z,t)],[u_z(x,y,z,t)])$

u2S(u):=matrix([diff(u[1,1],x)],[diff(u[2,1],y)],[diff(u[3,1],z)],[diff(u[2,1],z)+diff(u[3,1],y)],[diff(u[1,1],z)+diff(u[3,1],x)],[diff(u[1,1],y)+diff(u[2,1],x)])$

S: strain [] (%epsilon: normal strain, %gamma: shear strain)

(%i3)

S:matrix([%epsilon_x(x,y,z,t)],[%epsilon_y(x,y,z,t)],[%epsilon_z(x,y,z,t)],[%gamma_yz(x,y,z,t)],[%gamma_zx(x,y,z,t)],[%gamma_xy(x,y,z,t)])$

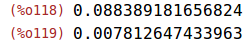

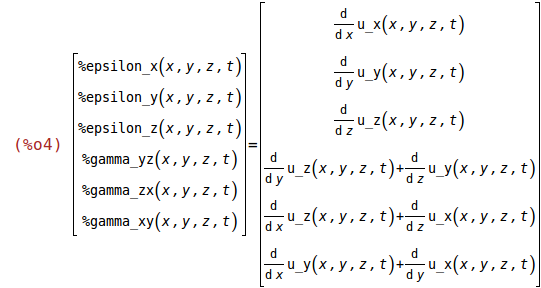

S=u2S(u);

(%i5)

grad(u):=matrix([diff(u[1,1],x,1),diff(u[1,1],y,1),diff(u[1,1],z,1)],[diff(u[2,1],x,1),diff(u[2,1],y,1),diff(u[2,1],z,1)],[diff(u[3,1],x,1),diff(u[3,1],y,1),diff(u[3,1],z,1)])$

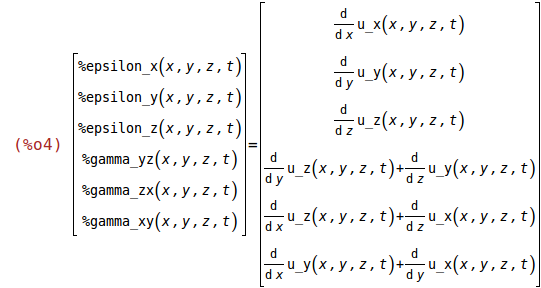

grad(u);

1/2*(grad(u)+transpose(grad(u)));

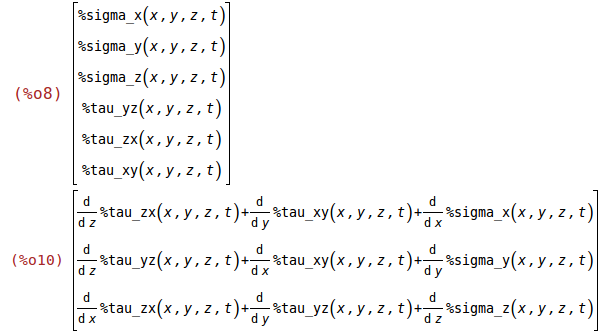

T: stress, force per unit area [N/m^2] (%sigma: normall stress, %tau: shear stress)

(%i8)

T:matrix([%sigma_x(x,y,z,t)],[%sigma_y(x,y,z,t)],[%sigma_z(x,y,z,t)],[%tau_yz(x,y,z,t)],[%tau_zx(x,y,z,t)],[%tau_xy(x,y,z,t)]);

divT(T):=matrix([diff(T[1,1],x,1)+diff(T[6,1],y,1)+diff(T[5,1],z,1)],[diff(T[6,1],x,1)+diff(T[2,1],y,1)+diff(T[4,1],z,1)],[diff(T[5,1],x,1)+diff(T[4,1],y,1)+diff(T[3,1],z,1)])$

divT(T);

1.2 Electric Displacement (D) and Electric Field (E)

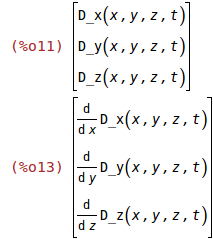

D: electric displacement [C/m^2]

(%i11)

D:matrix([D_x(x,y,z,t)],[D_y(x,y,z,t)],[D_z(x,y,z,t)]);

divD(D):=matrix([diff(D[1,1],x,1)],[diff(D[2,1],y,1)],[diff(D[3,1],z,1)])$

divD(D);

E: electric field [V/m]

(%i14)

E:matrix([E_x(x,y,z,t)],[E_y(x,y,z,t)],[E_z(x,y,z,t)]);

1.3 Linear Constitutive Tensors

The number of independent non-zero constants depends on the crystal symmetry. Y-cut (AT-, BT-, ST-cut) alpha-quartz is a material of crystal class 32.

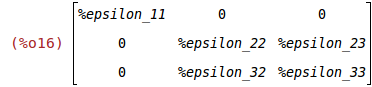

%epsilon: dielectric permittivity tensor [C/(V.m)] (at constant strain)

(%i15)

declare([%epsilon_0,%epsilon_11,%epsilon_22,%epsilon_23,%epsilon_32,%epsilon_33],[constant,real,scalar])$

%epsilon:matrix([%epsilon_11,0,0],[0,%epsilon_22,%epsilon_23],[0,%epsilon_32,%epsilon_33]);

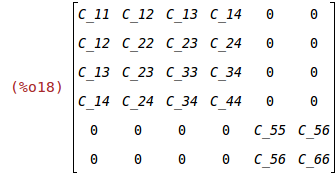

C: elastic stiffness tensor [N/m^2] (at constant electric field)

(%i17)

declare([C_11,C_12,C_13,C_14,C_22,C_23,C_24,C_33,C_34,C_44,C_55,C_56,C_66],[constant,real,scalar])$

C:matrix([C_11, C_12, C_13, C_14, 0, 0],[C_12, C_22, C_23, C_24, 0, 0],[C_13, C_23, C_33, C_34, 0, 0],[C_14, C_24, C_34, C_44, 0, 0],[0, 0, 0, 0, C_55, C_56],[0, 0, 0, 0, C_56, C_66]);

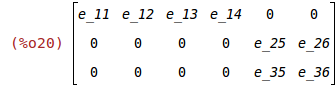

e: piezoelectricity tensor [C/m^2]

(%i19)

declare([e_11,e_12,e_13,e_14,e_25,e_26,e_35,e_36],[constant,real,scalar])$

e:matrix([e_11,e_12,e_13,e_14,0,0],[0,0,0,0,e_25,e_26],[0,0,0,0,e_35,e_36]);

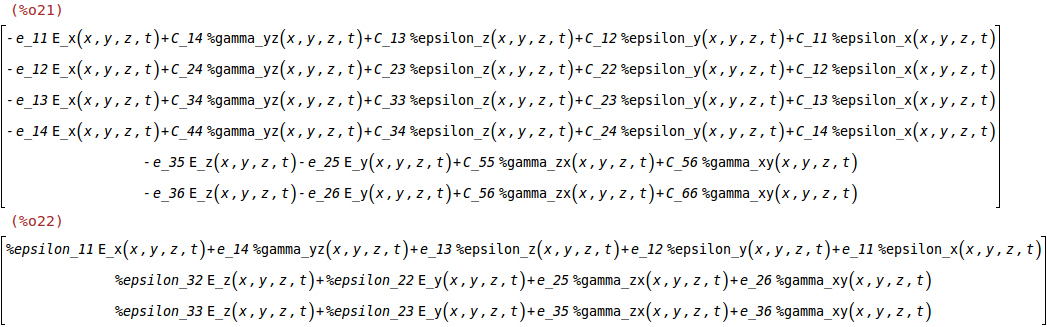

1.4 Lippmann's Linear Constitutive Equations in Charge-Stress Form

(%i21)

T:C.S-transpose(e).E;

D:e.S+transpose(%epsilon).E;

Some of the most important resonator phenomena (e.g. acceleration sensitivity) are due to nonlinear effects. Quartz has numerous higher order constants, e.g., 14 third-order and 23 fourth-order elastic constants, as well as 16 third-order piezoelectric coefficients are known (Source: "Quartz Crystal Resonators and Oscillators for Frequency Control and Timing Applications - A Tutorial", by John R. Vig, November 2008.)

2 Boundary Value Problem

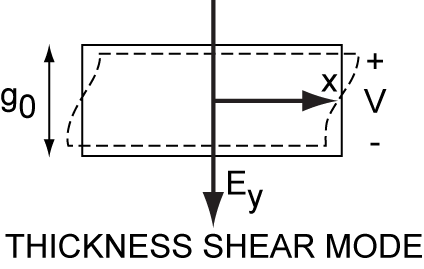

Assume a thickness-shear vibration of a AT-cut quartz plate around the Z-axis, excited by an electric field along the Y-axis.

Assume the plate can not move along the Y- and Z-axis: u_y(y,t)=0, u_z(y,t)=0.

(%i23)

%epsilon_x(x,y,z,t):=0$

%epsilon_y(x,y,z,t):=0$

%epsilon_z(x,y,z,t):=0$

%gamma_yz(x,y,z,t):=0$

%gamma_xz(x,y,z,t):=0$

%gamma_xy(x,y,z,t):=diff(u_x(y,t),y,1)$

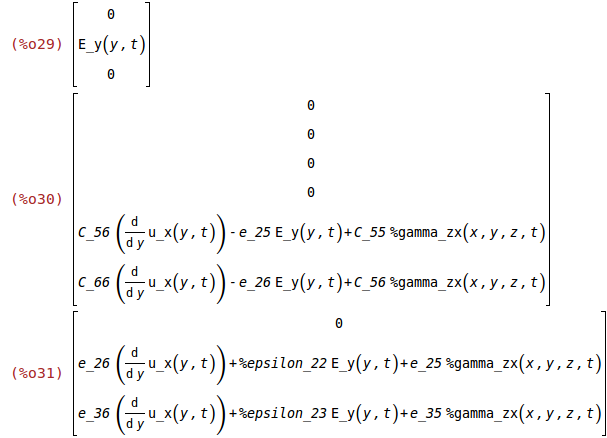

Assume the X- and Z-component of the electric field to be zero: E_x(x,y,z,t)=0, E_z(x,y,z,t)=0.

(%i29)

E:matrix([0],[E_y(y,t)],[0]);

T:ev(C.S-transpose(e).E);

D:ev(e.S+transpose(%epsilon).E);

2.1 Potential Energy

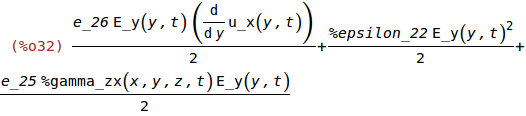

Electrostatic Energy Density, w_e

(%i32)

w_e:expand(ev(1/2*transpose(E).D));

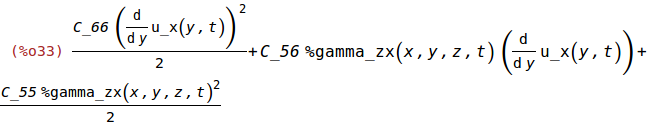

Elastic Energy Density, w_m

(%i33)

w_m:expand(ev(1/2*transpose(S).C.S));

Total Energy Density

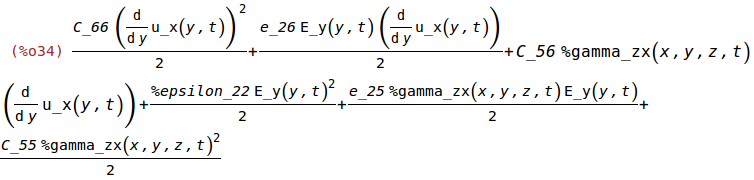

(%i34)

w_t:w_e+w_m;

2.2 Newton's Law of Motion for a Continuum [PDE in Quartz Volume]

Force density

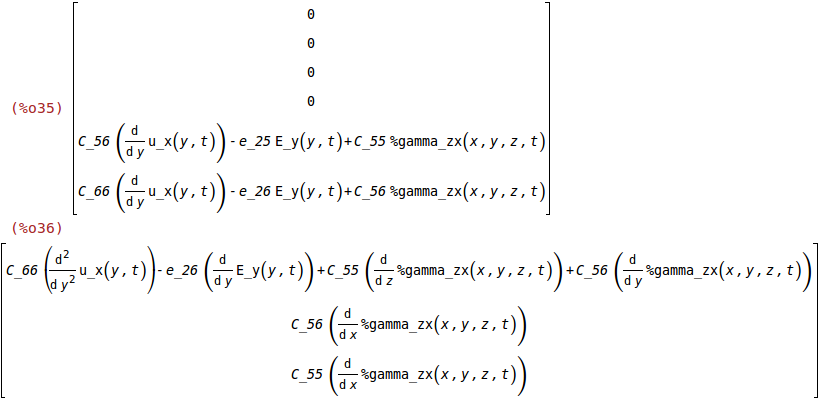

(%i35)

ev(T);

f:ratsimp(divT(ev(T)));

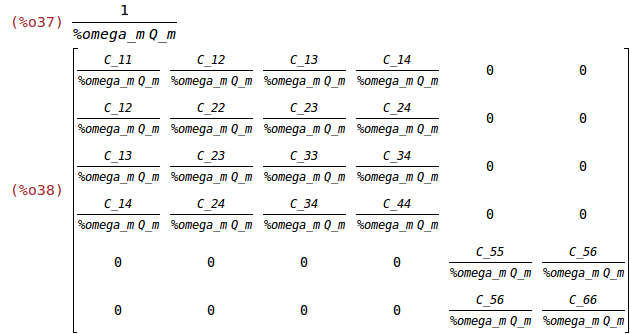

Viscosity and Q Factor

%eta: viscosity tensor [N/(m^2.s)]

%tau_m is the motional time constant

%omega_m is the mechanical resonant radian frequency

Q_m is the mechanical Q factor

(%i37)

%tau_m:1/(%omega_m*Q_m);

%eta:%tau_m*C;

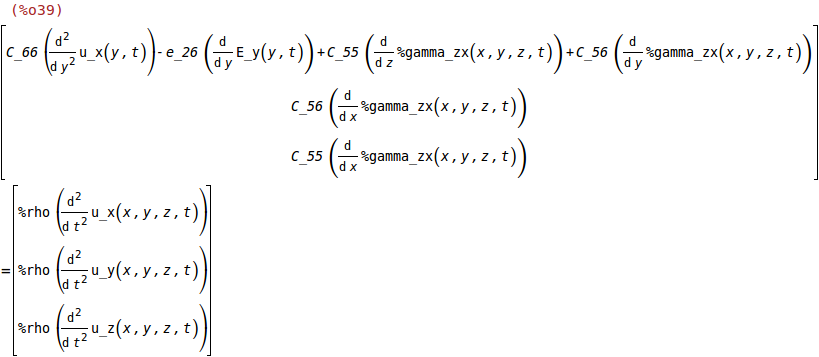

Newton's Equation of Motion

%rho: mass density [kg/m^3]

(%i39)

f=%rho*diff(u,t,2);

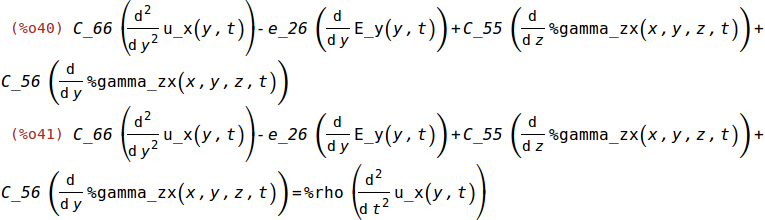

(%i40)

f_x:ev(f[1,1]);

f_x=%rho*diff(u_x(y,t),t,2);

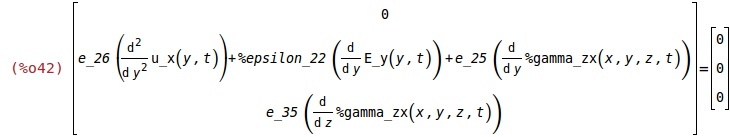

3 Gauss' Law [PDE in Quartz Volume]

(%i42)

divD(ev(D))=matrix([0],[0],[0]);

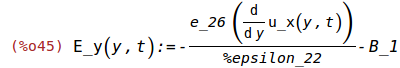

Calculating 'diff(E_y(y,t),y,1)

(%i43)

-(e_26*('diff(u_x(y,t),y,2)))/%epsilon_22;

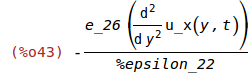

Calculating E_y(y,t)

B_1 is an integration constant.

(%i44)

declare([B_1],[constant,real,scalar])$

define(E_y(y,t),-(e_26*(diff(u_x(y,t),y,1)))/%epsilon_22-B_1);

4 Boundary Conditions

Assume a solution u_x(y,t):=A_1*sin(%xi*y)*exp(%i*%omega_m*t) with %xi:sqrt(%rho/(C_66*(1+k_26^2)))*%omega

k_26: sqrt(e_26^2/(%epsilon_22*C_66))

(%i46)

declare([A_1],[constant,real,scalar])$

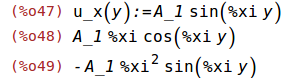

u_x(y):=A_1*sin(%xi*y);

ratsimp(diff(u_x(y),y,1));

ratsimp(diff(u_x(y),y,2));

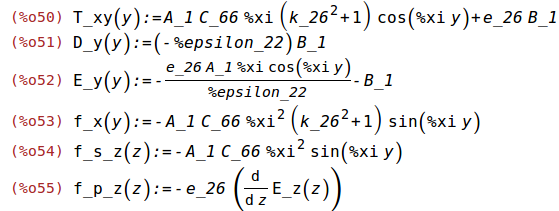

(%i50)

define(T_xy(y),C_66*(1+k_26^2)*%th(2)+e_26*B_1);

D_y(y):=-%epsilon_22*B_1;

define(E_y(y),-(e_26*%th(4))/%epsilon_22-B_1);

define(f_x(y),C_66*(1+k_26^2)*%th(4));

define(f_s_z(z),C_66*%th(5));

define(f_p_z(z),-e_26*(diff(E_z(z),z,1)));

Calculating the potential %Phi(y)

B_2 is an integration constant.

(%i56)

declare([B_2],[constant,real,scalar])$

%Phi(y):=e_26*u_x(y)/%epsilon_22+B_1*y+B_2;

%tau_xy(z=-g_0/2)=0,

%tau_xy(z=g_0/2)=0,

%Phi(z=g_0/2)-%Phi(z=-g_0/2)=V,

with,

g_0: thickness [m]

V: applied voltage [V]

(%i58)

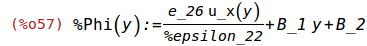

solve([ev(T_xy(g_0/2))=0,ev(%Phi(g_0/2)-%Phi(-g_0/2))=V(t)],[A_1,B_1])$

A_1:ratsimp(ev(A_1,%));

B_1:ratsimp(ev(B_1,%th(2)));

ratsimp(ev(A_1,%xi=%pi/g_0));

ratsimp(ev(B_1,%xi=%pi/g_0));

5 Elastic Wave Equation and Christoffel Equation

(See: http://sepwww.stanford.edu/public/docs/sep92/hector1/paper_html/node2.html)

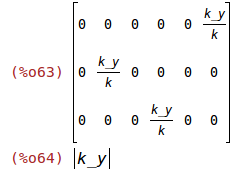

(%i63)

K:ev(1/k*matrix([k_x,0,0,0,k_z,k_y],[0,k_y,0,k_z,0,k_x],[0,0,k_z,k_y,k_x,0]),k_x=0,k_z=0);

k:ev(sqrt(k_x^2+k_y^2+k_z^2),k_x=0,k_z=0);

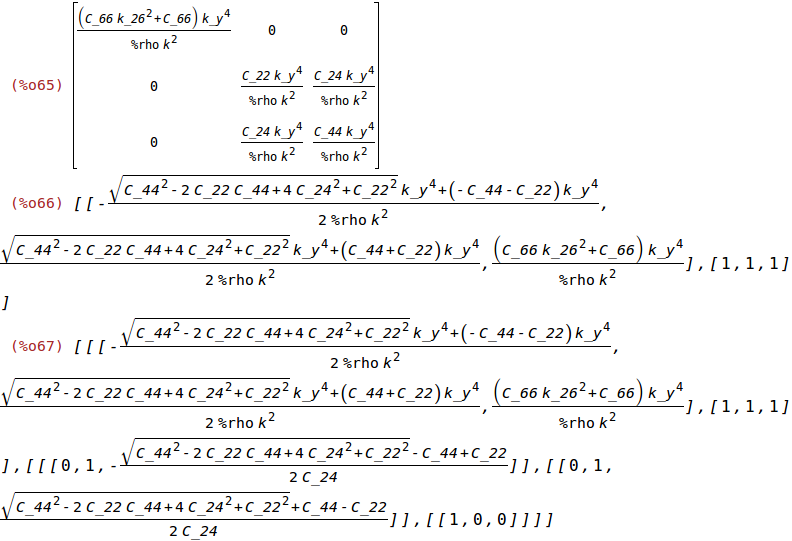

(%i65)

M:ratsimp(k^2/%rho*K.subst(C_66*(1+k_26^2),C_66,C).transpose(K));

ratsimp(eigenvalues(M));

ratsimp(eigenvectors(M));

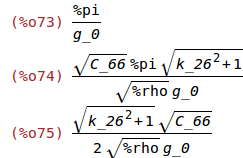

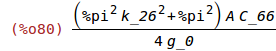

The vibration frequency of the thickness-shear mode, f_m, can be used to determine the thickness of the Y-cut alpha-quartz plate, g_0

(%i68)

declare([%rho,C_66,g_0,k_26],[constant,real,scalar])$

assume(%rho>0)$

assume(C_66>0)$

assume(g_0>0)$

assume(k_26>0)$

k_y:2*%pi/(2*g_0);

%omega_m:sqrt(ev((k_y^2*C_66*(1+k_26^2))/(%rho)));

f_m:1/(2*%pi)*%omega_m;

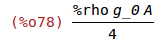

m is the effective mass.

A is the electrode area.

(%i76)

declare([A],[constant,real,scalar])$

m:A*integrate(u_x(y)^2*%rho,y,0,g_0/2)/A_1^2$

m:ev(m,%xi=sqrt(%rho/(C_66*(1+k_26^2)))*%omega_m);

k_1_eff is the linear spring constant.

(%i79)

solve([%omega_m=sqrt(k_1_eff/m)],[k_1_eff])$

ev(k_1_eff,%);

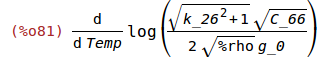

Tf is the linear temperature coefficient of frequency.

(%i81)

Tf:'diff(log(f_m),Temp);

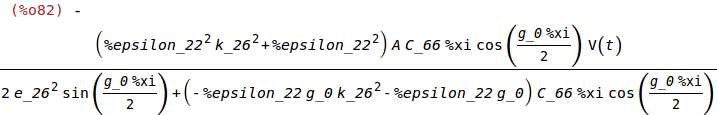

6 Charge, q, on the Electrodes

Boundary condition for D

A is the electrode area.

(%i82)

q:ratsimp(-D_y(g_0/2)*A);

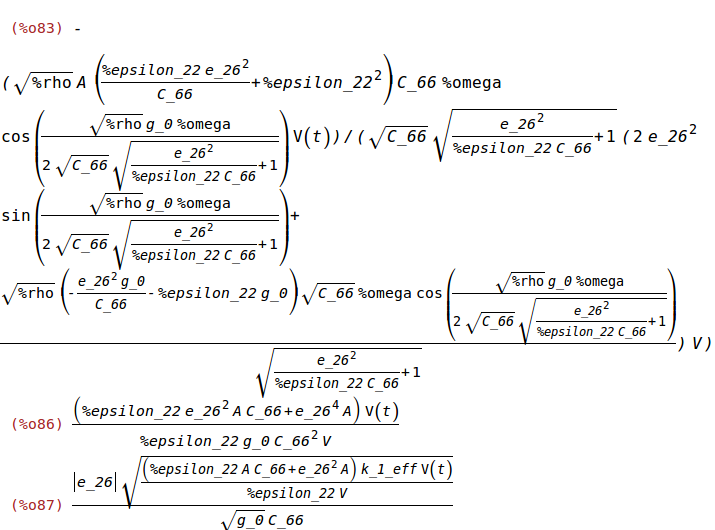

7 Motional Capacitance, C_m, Static Capacitance, C_0, and Transduction Factor, %eta

(%i83)

C_XTAL:ev(q/V,

%xi=sqrt(%rho/(C_66*(1+e_26^2/(%epsilon_22*C_66))))*%omega,

k_26=sqrt(e_26^2/(%epsilon_22*C_66)));

C_0:ratsimp(limit(C_XTAL,%omega,0));

ratsimp(C_XTAL-C_0)$

C_m:ratsimp(ev(k_26^2*C_0,

k_26=sqrt(e_26^2/(%epsilon_22*C_66))));

%eta:ratsimp(ev(sqrt(k_26^2*k_1_eff*C_0),

k_26=sqrt(e_26^2/(%epsilon_22*C_66))));

8 Material Parameters

8.1 AT-Cut alpha-Quartz (Trigonal Structure, Crystal Class 32)

(See "Elastic and Piezoelectric Constants of Alpha-Quartz", by R. Bechmann, American Physical Society Phys. Rev., vol. 110, no. 5, pp. 1060-1061, June 1958)

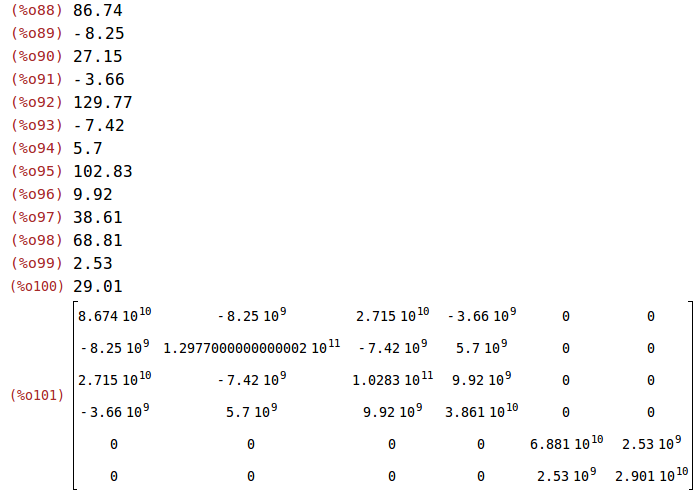

(%i88)

C_11:86.74;

C_12:-8.25;

C_13:27.15;

C_14:-3.66;

C_22:129.77;

C_23:-7.42;

C_24:5.70;

C_33:102.83;

C_34:9.92;

C_44:38.61;

C_55:68.81;

C_56:2.53;

C_66:29.01;

C:1e9*matrix([C_11, C_12, C_13, C_14, 0, 0],[C_12, C_22, C_23, C_24, 0, 0],[C_13, C_23, C_33, C_34, 0, 0],[C_14, C_24, C_34, C_44, 0, 0],[0, 0, 0, 0, C_55, C_56],[0, 0, 0, 0, C_56, C_66]);

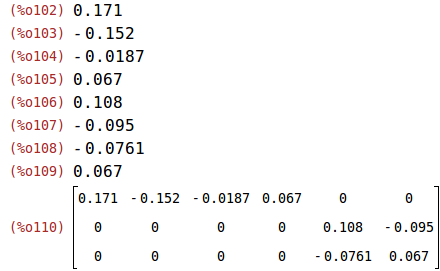

(%i102)

e_11:0.171;

e_12:-0.152;

e_13:-0.0187;

e_14:0.067;

e_25:0.108;

e_26:-0.095;

e_35:-0.0761;

e_36:0.067;

e:matrix([e_11,e_12,e_13,e_14,0,0],[0,0,0,0,e_25,e_26],[0,0,0,0,e_35,e_36]);

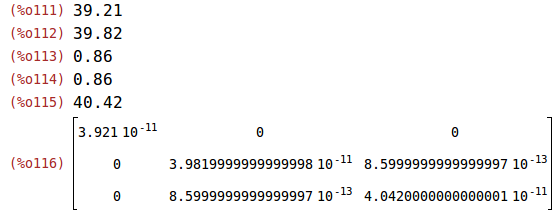

(%i111)

%epsilon_11:39.21;

%epsilon_22:39.82;

%epsilon_23:0.86;

%epsilon_32:0.86;

%epsilon_33:40.42;

%epsilon:1e-12*matrix([%epsilon_11,0,0],[0,%epsilon_22,%epsilon_23],[0,%epsilon_32,%epsilon_33]);

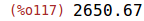

(%i117)

%rho:2650.67;

k: piezoelectric coupling coefficient

(%i118)

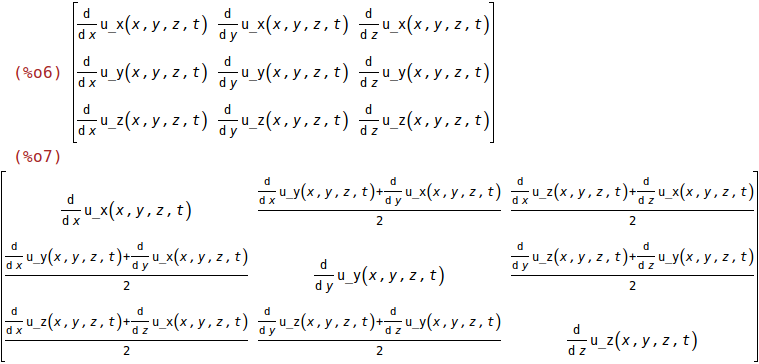

k_26:sqrt(e_26^2/(C_66*1e9*%epsilon_22*1e-12));

k_26^2;